A cutaway model is an object that is partially cut open to illustrate its internal structure and how it works. Often the cut edges or individual functional areas are colored for better visibility. Cut-away models can be movable and can better illustrate the respective function through targeted lighting of individual areas, in an internal combustion engine, for example, through moving pistons, shafts and valves as well as ignition and combustion indicated by lighting.

Sectional models are used, among other things, for education and demonstration, and can, for example, show the operation of motors, pumps, car chassis and reinforcements etc. Even after 3D modeling and computer-aided design have become more common, sectional models ( cutaway models) are still used to showcase products, as you then get to see how the product appears and works in reality with actual parts and components.

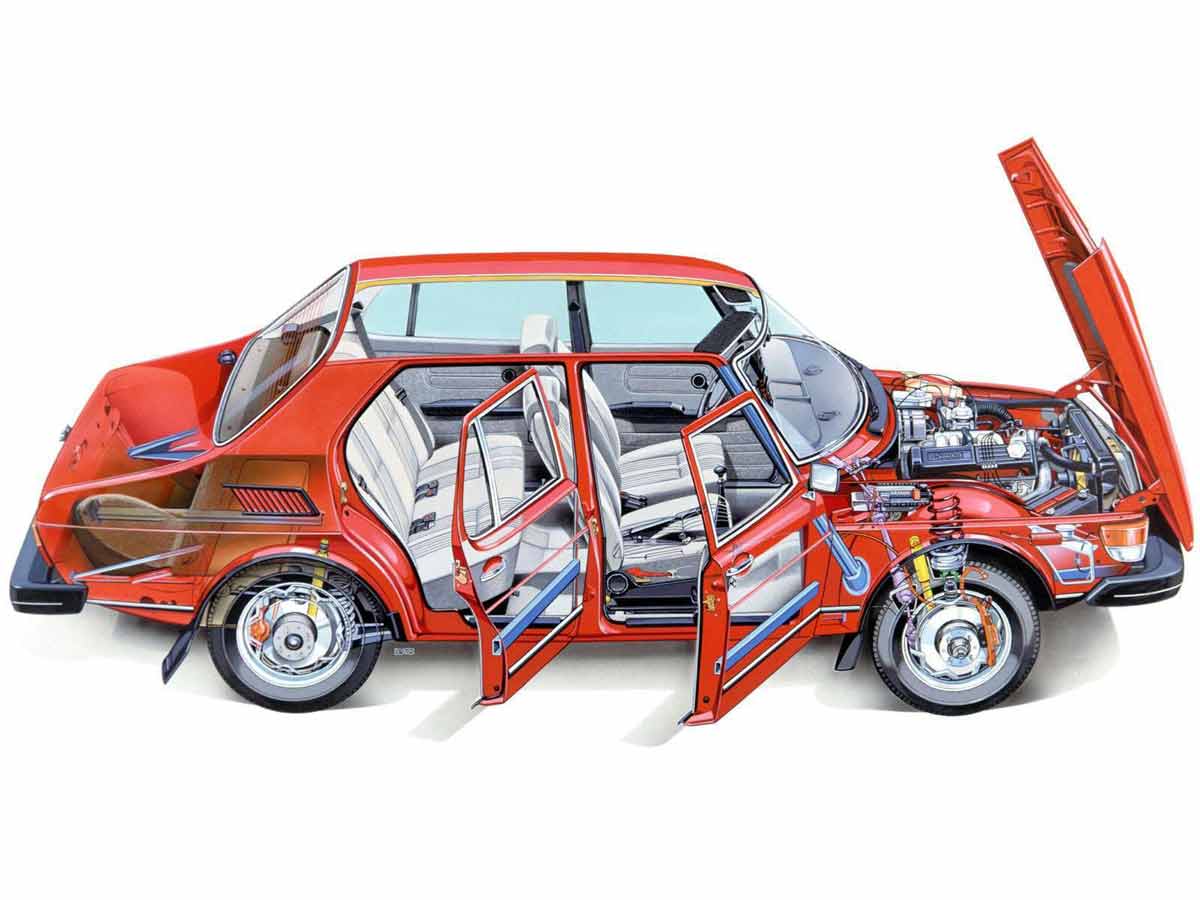

Those cutaway models that interest us are a cutaway model of Saab cars and you can see them mostly in the Saab Museum in Trollhattan, or in one of the technical museums, and technical classrooms.

For all those who have not had the opportunity to visit the museum in Trollhattan, in the video above they can see a cross section of the Saab 99 model showing the chassis structure of this car and especially – strengthening the structure where necessary – or where Saab engineers determined it was necessary.

Each vehicle must have its own structural base which serves to carry and unite all other assemblies or parts. This structural base consists of a lower part called the chassis and an upper part or body. However, today there are such bodies that serve both as a chassis and as a body, they are self-supporting bodies.

The material from which the chassis is made is very different. Steel is most often used as a material, then steel alloyed with chromium and nickel, steel with the addition of molybdenum and others. A worn-out chassis also means a worn-out vehicle, so not much can be done from a maintenance and repair standpoint. Chassis deformed in an accident or overload is very risky to correct and only exceptionally can the transverse beams be changed. Sometimes the chassis is strengthened to stiffen. This is done with additional brackets that are welded or nailed to the longitudinal brackets, and belts or connecting sheets can be welded in the same way.