No car manufacturer has been as innovative with such small funds as Saab’s car manufacturing in Trollhättan. In this post, in one image, we present the interesting inventions from Saab’s nearly eighty-year history.

Here are Saab’s “craziest” inventions, coolest, smartest and most heartwarming inventions from Saab’s car manufacturing in Trollhättan, from front-wheel drive and transverse engine on the Saab 92 1947, via monster prototypes, self-repairing shock absorbers and cup holders to highly advanced engine systems.

Table of Contents

1947: Front-wheel drive and transverse engine

June 10, 1947: The new Saab 92 is covered at Saab’s trade fair in Linköping by order of CEO Ragnar Wahrgren. Attending were, among others, the flight general Nils Söderberg.

The Saab car was born. The streamlined Saab 92 had both front-wheel drive and a transverse engine. Then something curious and strange, today standard in the car world for many years.

1959: Saab’s Monster

What do you do when the two-stroke engine is modestly small and the company’s development resources are as small as grains of sand? Well, you put in two engines. The year was 1959. Saab’s engineers wanted to develop a car with a more powerful engine. And here comes Saab’s soul, the one that constantly balances in the borderland between cutting-edge innovation and home-made emergency solutions: The engineers in Trollhättan took a toreador red Saab 93 from the production line, lightened it to unnecessary weight and installed two standard cross-mounted 748 cc two-stroke engines.

Suddenly, the small Saab, with a weak engine, gained exceptional power – as much as 100 horsepower and a top speed of 196 kilometers per hour, and the speed record was set at Såtenäs Airport. The prototype was called “Monster“.

1970: First in the world – Headlamp Wipers

Perfect for Swedish conditions. Saab created a new industry standard that saved many lives. But today, headlight dryers are considered too expensive and have been replaced by poorer high-pressure flushing. It is well known that a lot of slush comes on the headlights, in winter.

Saab’s development team was given the task of solving the problems of muddy headlights, and it succeeded. Result: Each time you flushed the windshield, a high-pressure jet was sent to the headlights, and the wiper blades pulled a few turns. Saab’s construction would withstand 1.5 million work strokes in temperatures between +40 and −30 degrees and 94 percent of the glass surface was wiped clean. The headlight Wipers became the industry standard. In 1974, all car brands on the Swedish market must have headlight wipers.

1971: Self-repairing bumper

The reason these bumpers are called “self-repairing” is because they can come back into shape (slowly) after an impact dents them. There are no consequences in a collision of up to 8 kilometers per hour. The only thing that needed to be replaced after that was the chrome-plated stainless steel strap in the middle of the bumper.

Saab’s bumpers in 1971 were black, smart and built on a steel rail attached to the load-bearing beams under the front. The bottom line was that repairs were cheaper. Also, In the US, Saab owners received a 15 percent discount on the insurance premium.

1971: Electrically heated seats

In 1971, not only did self-repairing bumpers come on the then almost new Saab 99. The Saab engineers had an ace up their sleeve for us frozen northerners: during those icy days, it was wonderful to get warm in the background. Saab introduced a remarkable automatic system with thermostatically controlled heating coils in both the seat cushion and backrest. After many hours of testing in Saab’s cold room, the engineers determined that the heat would automatically turn on below plus 14 degrees and only turn off when it burned properly under the butt, at 27 degrees.

1976-77: Saab Turbo

No word in Saab circuits is as charged as the turbo, which has been called Saab’s great world innovation. There’s only one thing: It’s wrong. Saab was not the first. As early as 1962, the turbo was introduced in the Chevrolet Monza Spyder, a car that was produced in 50,000 units until 1966. Subsequently, the BMW 2002 Turbo was launched with 170 horsepower in 1973, in the midst of the oil crisis, and only 1,672 units were produced. And the Porsche 911 Turbo was launched in 1974.

But at the Frankfurt Motor Show in September 1977, a Saab was launched that would really impress the trendsetters. The stand shone from a mother-of-pearl white Saab 99 turbo with 145 horsepower. It would become Saab’s single most important car of all time, raising both sales and brand significantly.

Turbo means, in simple terms, that a small and relatively fuel-efficient engine can be really fast. The energy of the exhaust gases is used via a turbocharger to force more air and fuel into the engine to get more power.

But it was extremely close that the Saab Turbo never became a reality. In 1976, the turbo project was on the verge of shut down after five years of work. The turbo became overheated. Then the responsible Saab engineers Bengt Gadefelt and Per Gillbrand came up with the solution, an overpressure valve, called a wastegate, which led the exhaust gases past the turbo at a certain pressure – think about doing a bypass operation.

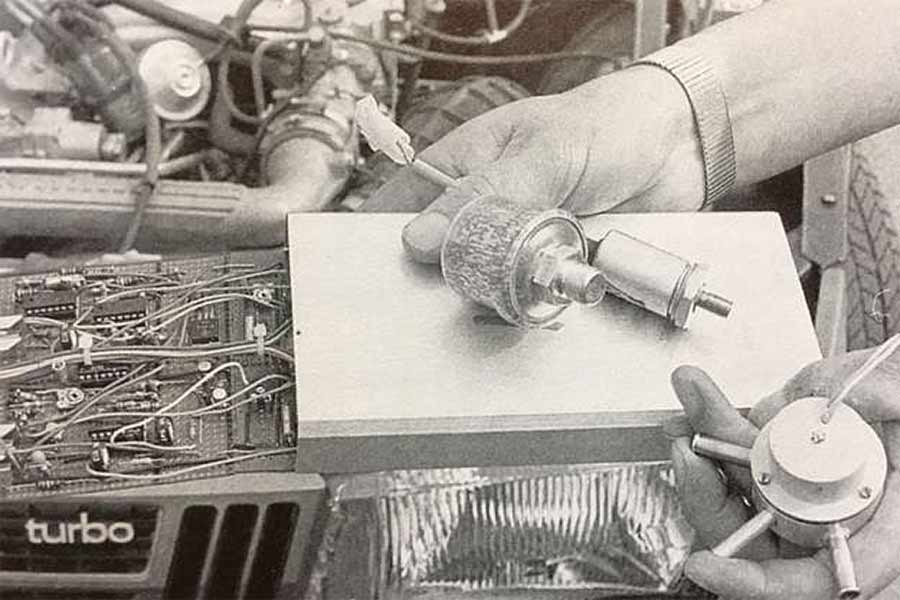

1980: APC – goodbye knocks

Automatic Performance Control – APC – was developed at Saab under the leadership of Per Gillbrand to handle variations in petrol quality. In pure Swedish: So that you could refuel everything from 93 to 98 octane petrol. The magic APC regulated the turbocharger’s boost pressure and allowed the engine to run efficiently in all petrol conditions.

And the ignition key by the hand brake on all 99 900