Over its long history, the Saab-Scania Group had accumulateda wealth of experience in the turbocharging of truck and bus engines when the turbocharged car engine for everyday motoring was launched in 1977.

Saab was one of the world’s first car manufacturers to adapt the turbocharging technique to everyday motoring. In a Saab Turbo, the boost on performance starts at low engine speeds.The engine delivers its peak torque at a mere 3000 rpm.

This provides enhanced power resources for overtaking, without the need for downshifting. The engine is designed for normal, everyday motoring, instead of the extremly high topspeeds demanded by a competition driver.

Table of Contents

How Saab turbo engines work

The Performance of the turbocharged four-cylinder Saab engine can match that of many six-cylinder or eight-cylinder engines. But experience has shown that the full power resources of an engine remain unsed durin 80/85 per cent of the motoring time, and the turbocharger is the “idling”, without affecting engine output. During this time, the engine has the fule economy of the naturally-aspired 4-cylinder fuel injection engine.

What is it for and how does a turbocharger work?

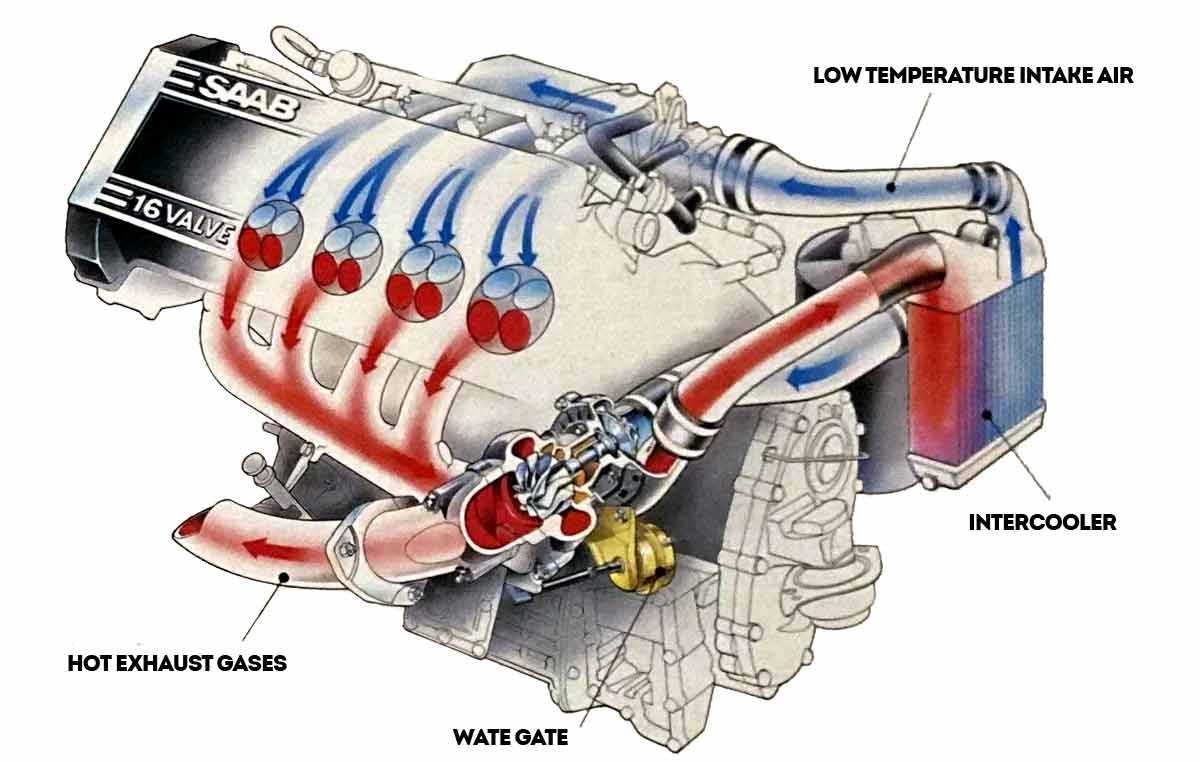

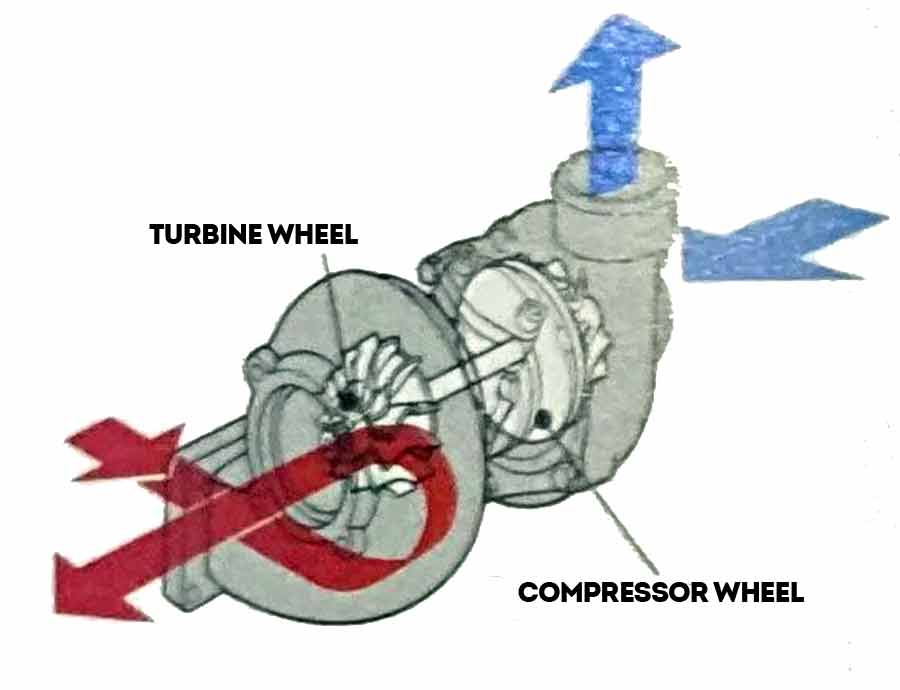

The turbocharger consists of a turbine and a compressor.The exhaust gases flow through the turbine, while the compressor boosts the engine intake air. In brief, the system operates as follows. The engine exhaust gases flow through the turbine casing, in which a bladed wheel is induced to rotate a very higth speed – up to 120,000 revolutions per minute. The turbine wheel drives the compressor directly on a common shaft.

Turbocharger Composition

The turbocharger consists of two wheels mounted on a common rotating shaft. One of the wheels – the turbine – is driven by the exhaust gases. The other wheel – the compressor – is located in the intake system of the engine, and its function is to compress the intake air. When the driver presses down the accelerator pedal, the flow of exhaust gases and their velocitywill increase, and the wheels will therefore rotate at increasing speed. At acertain speed, the compressor start boosting the pressure in the intake system, so that the engine will be suppiled with more air than it would if it were naturally aspired. A regulator ensures that the correct air pressure is maintained.

When the turbocharger has reached a certain speed, the compressor will start to boost the intake air pressure. Due to this pressure increase, more air will be forced into the cylinders, and more fuel can thus be injected an burned. The engine delivers more energy per piston stroke, and the torque and power of the engine will therefore increase. The turbine is eqipped with a waste gate – a pressure control valve which automatically bleeds off any excess pressure should it develop.

If the boost pressure should exceed the predetermined value in spite of the waste gate, a pressure switch will temporarily interrupt the fuel supply. The boost pressure can be monitored on a pressure gauge in the instrument panel. The system also includes engine overspped protection which cuts off fuel injection should the engine speed exceed 6000 rpm and resumes fuel delivery when the engine speed has fallen to an acceptable level. Thus the engine is monitored by two safety systems that prevent overloading.

The exhaust gases from the turbocharged engine are at roughly the same temperature as those leaving a conventional fuel injection engine, but the gas flow is higher. The components of the turbo engine, which are exposed to high temperatures, are protected, modified or upgraded to withstand the higher engine power by a comfortable margin.

The engine oil cooler and water-cooled bearing housings on the turbocharger ensure that the engine oil temperatures maintains a steady, low temperature even after hard driving. The turbocharger engine is also equipped with a radiator with a larger number of cooling passages and a radiator fan with higher rating that that of the naturally aspired engine. Whenever necessary, the fan runs of after the ignition has been switched off.

What is the purpose of the intercooler?

When the engine intake air has been compressed in the turbocharger, its temperature will rise. Warm air has a larger volume than cold air. By routing compressed air through an intercooler, its temperature is reduced by about 110° F (43°C) before the air reaches the engine. As a result, more air can be acommodated in the engine cylinders. And the higher the density of the air, the higher its oxygen content. So more fuel can be injected and burned, and the engine power thus increases.