Table of Contents

Saab has always been known for its innovative approach to automotive engineering, and two of the most intriguing projects in its history were the Saab Combustion Control (SCC) system and the Variable Compression Engine. These projects, though ultimately shelved, were pioneering efforts that showcased Saab’s commitment to pushing the boundaries of engine technology.

In this article, we delve into these advanced technologies through the lens of Svante Lejon, a former Saab engineer (for the last 15 years he has been working on the development of engines for Scania trucks) and inventor with many patents who played a key role in their development. His insider perspective reveals the challenges, triumphs, and decisions that shaped the fate of these groundbreaking innovations.

The Saab Combustion Control (SCC) System: A Missed Opportunity

The SCC system was a cutting-edge technology developed by Saab to improve fuel efficiency and reduce emissions. Svante Lejon, who was deeply involved in the project, shared some valuable insights into the development and the eventual demise of the SCC system.

The Promise and Challenges of the SCC System

According to Lejon, the SCC system performed exceptionally well during its development stages. One of the primary concerns was the grounding of the spark current, which was primarily channeled through the piston rings. Fortunately, no issues were found with the piston rings or the connecting rod bearings, affirming the system’s robustness.

However, the SCC system faced significant hurdles that prevented it from reaching production. Lejon cited two main reasons for this.

First, the project was developed alongside the Variable Compression Engine, which stretched Saab’s financial resources thin. The limited budget made it challenging to fully develop both technologies simultaneously.

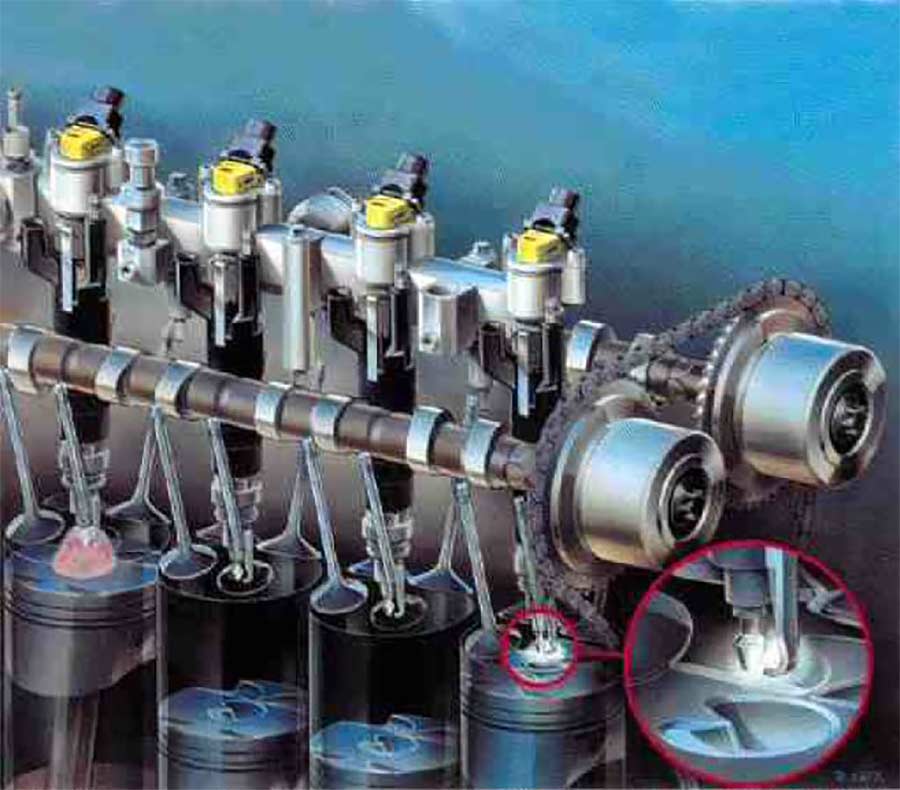

Second, the unique design of the SCC system required a combined injector and spark plug unit, which was intended to last the lifetime of the engine. Unfortunately, no spark plug supplier was willing to produce this component, as it would eliminate the recurring revenue from replacement spark plugs—a key profit source for these companies.

The Shift to a Conventional Design

Faced with these challenges, Saab engineers developed an alternative design using a conventional spark plug with a side-mounted injector, still utilizing air-guided fuel injection based on Orbital technology. This version also performed well in pre-development stages but was ultimately abandoned due to financial constraints. During this period, GM’s acquisition of 100% of Saab shifted the company’s focus to other projects, such as boosting the aluminum Saturn engine and the GM V6. The SCC system, a potential game-changer in engine technology, was left behind as GM prioritized other developments.

The Variable Compression Engine: A Double-Edged Sword

Another significant project that Lejon worked on at Saab was the Variable Compression Engine, a technology that aimed to maximize performance and efficiency by varying the engine’s compression ratio. This project, however, proved to be a mixed blessing for Saab.

The Potential and Pitfalls of Variable Compression

Lejon recalls that while the Variable Compression Engine showed great promise, it also posed significant challenges, particularly with noise issues inherent in its construction. These noise problems were extremely difficult to overcome, and the anticipated benefits of variable compression were not as substantial as initially thought.

Despite these issues, the project consumed almost all of Saab’s pre-development resources, effectively strangling the boosted air-guided Gasoline Direct Injection (GDI) project, which was running in parallel. Lejon reflects that had Saab allocated resources differently, they could have been 5-7 years ahead of their competitors in developing highly efficient and powerful GDI engines. This missed opportunity could have provided Saab with a much-needed sales boost and possibly altered the company’s fate.

Reflections on Saab’s Engineering Legacy

Svante Lejon’s insights provide a rare glimpse into the complex decision-making processes and the challenges faced by Saab during the development of the SCC system and the Variable Compression Engine. Both projects were remarkable in their innovation, yet they were ultimately overshadowed by financial limitations and strategic decisions influenced by external pressures, particularly from GM.

The SCC system, with its potential to revolutionize fuel efficiency and emissions control, and the Variable Compression Engine, which aimed to redefine performance and efficiency, are testaments to Saab’s engineering prowess. Although these technologies never made it to production, they remain an important part of Saab’s legacy, illustrating the company’s relentless pursuit of innovation.

What Could Have Been

The story of the SCC system and the Variable Compression Engine is a story of what could have been for Saab. These technologies represented the cutting edge of automotive engineering in their time, yet external factors and strategic decisions prevented them from reaching their full potential. As we reflect on these projects, we are reminded of Saab’s commitment to innovation and the challenges that come with pioneering new technologies. While these projects may have been sidelined, the lessons learned continue to resonate within the automotive industry, influencing the development of future technologies.

Svante Lejon’s firsthand account of these developments offers invaluable insights into Saab’s engineering efforts and the factors that shaped the company’s path. His reflections remind us of the importance of resource allocation and strategic decision-making in the successful development of groundbreaking technologies.