Table of Contents

- 1 Introduction to Saab’s Combustion Control System

- 2 The SCC System: A Global Solution for Emission Control

- 3 Direct Injection and Lambda 1 with SCC

- 4 Reducing Pumping Losses for Enhanced Fuel Efficiency

- 5 The Role of the Three-Way Catalytic Converter

- 6 Achieving Lower Emissions Through Exhaust Gas Utilization

- 7 Key Components of the SCC System

- 8 Saab’s Commitment to Eco-Friendly Innovation: The Impact of the SCC System

Introduction to Saab’s Combustion Control System

In the early 2000s, Saab Automobile made significant strides in engine technology with the development of the Saab Combustion Control (SCC) system. Originating from the Saab Engine Development Department, this innovative system positioned Saab at the forefront of automotive engineering, particularly within the General Motors (GM) Group. The SCC system was a further development of the spark-to-piston concept that Saab had unveiled at the Frankfurt Motor Show in 1995, integrating cutting-edge technology to meet stringent emission standards globally.

The SCC System: A Global Solution for Emission Control

The SCC system was designed to address the varying environmental regulations in different regions. In the United States, the focus was on reducing nitrogen oxide and hydrocarbon emissions, while in Europe, the emphasis was on cutting carbon dioxide emissions. By achieving these goals, the SCC system ensured compliance with the world’s most demanding environmental standards, preparing it for integration into the next generation of Saab vehicles.

Direct Injection and Lambda 1 with SCC

One of the key innovations of the SCC system was its ability to leverage the benefits of direct injection while maintaining the ideal air-to-fuel ratio, known as lambda 1. This was achieved by using compressed air to inject fuel directly into the cylinder through a unique spark plug injector.

Unlike other direct injection systems, Saab’s approach maintained the lambda 1 ratio by utilizing exhaust gases instead of air to fill the cylinder. This method not only preserved the necessary air-to-fuel ratio but also eliminated the need for a special catalytic converter, allowing the use of a conventional three-way catalyst.

Reducing Pumping Losses for Enhanced Fuel Efficiency

A significant advantage of the SCC system was its ability to reduce pumping losses, which occur when an engine operates at low load with a partially closed throttle. By supplying only the necessary amount of fuel and air, with the remainder of the cylinder filled with inert exhaust gases, the SCC system minimized the extra energy required to draw in air. This reduction in pumping losses led to lower fuel consumption, enhancing overall engine efficiency.

The Role of the Three-Way Catalytic Converter

Despite the advanced technology of the SCC system, the three-way catalytic converter remained the most crucial component for controlling exhaust emissions. Capable of catalyzing up to 99% of harmful emissions, the converter’s core, coated with precious metals like platinum and rhodium, facilitated the conversion of carbon monoxide, hydrocarbons, and nitrogen oxides into less harmful substances such as carbon dioxide, water, and nitrogen.

Achieving Lower Emissions Through Exhaust Gas Utilization

The SCC system significantly reduced fuel consumption and exhaust emissions by incorporating a large proportion of exhaust gases into the combustion process. This approach not only decreased fuel usage by up to 10% but also ensured compliance with the stringent Ultra Low Emission Vehicle 2 (ULEV2) standards set to be implemented in 2005. Compared to contemporary Saab engines, the SCC system nearly halved carbon monoxide and hydrocarbon emissions and reduced nitrogen oxide emissions by 75%.

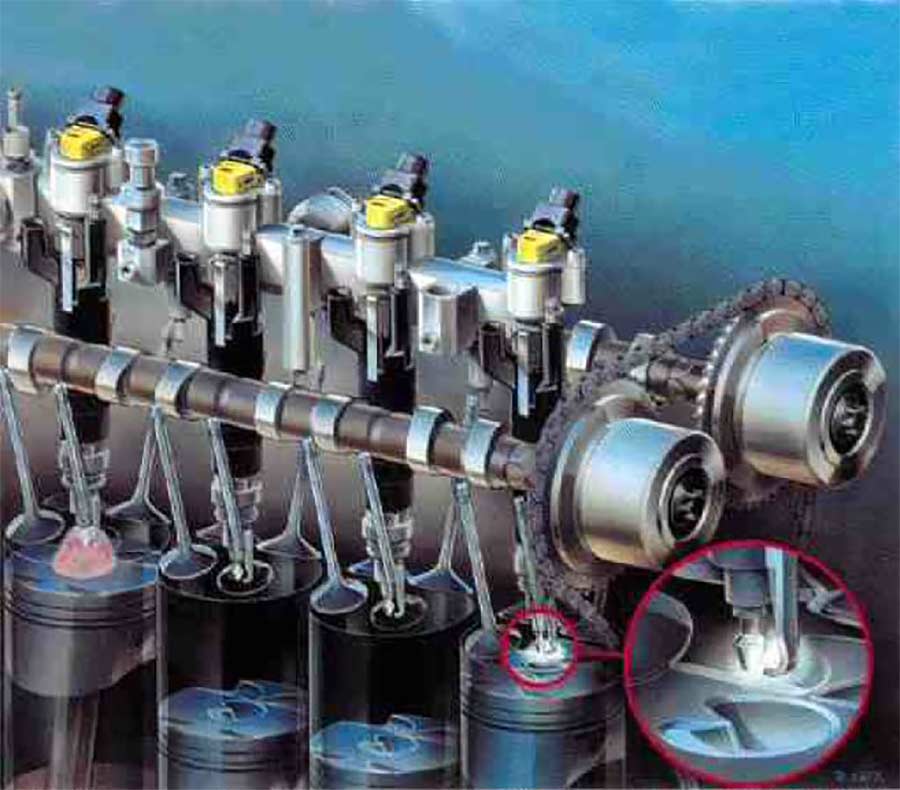

Key Components of the SCC System

The SCC system’s effectiveness stemmed from three main components: direct injection of petrol, variable valve timing, and variable spark gap.

Air-Assisted Fuel Injection with Turbulence Generator

The spark plug injector (SPI) unit, integrating the fuel injector and spark plug, used compressed air to inject fuel directly into the cylinder. This injection was followed by a brief blast of air, creating turbulence that facilitated quicker and more efficient combustion.

Variable Valve Timing

Using camshafts with variable cams, the SCC system allowed for precise control over the opening and closing of the inlet and exhaust valves. This enabled the optimal mixing of exhaust gases with combustion air, maintaining the ideal lambda 1 ratio under nearly all operating conditions. Up to 70% of the cylinder’s contents during combustion could consist of exhaust gases, depending on the engine’s operating conditions.

Variable Spark Plug Gap with High Spark Energy

The SCC system featured a spark plug with a variable gap ranging from 1 to 3.5 mm. This design, combined with a high spark firing energy of 80 mJ, ensured reliable ignition of the air/fuel mixture, even when heavily diluted with exhaust gases.

Saab’s Commitment to Eco-Friendly Innovation: The Impact of the SCC System

The development of the SCC system underscored Saab’s commitment to pioneering advanced engine technologies that balanced performance with environmental responsibility. By integrating direct injection, variable valve timing, and a variable spark gap, Saab engineers created an engine system that not only met but exceeded the stringent emission standards of the early 21st century. As we reflect on these innovations, it’s clear that Saab’s legacy in automotive engineering continues to influence the industry’s pursuit of more efficient and eco-friendly engine technologies.

I like your work about SAAB.From a SAAB owner.

Idea killed by GM, but if Saab had got it out on the market it would have been 30+ years before others

What about the twin turbo idea implemented by Saab on the diesel engine? 🤷♂️

E.G. the 1.9 vector.

I have one.. 50+ mpg & 180 bhp

A brand that should never have been allowed to disappear thanks to GM’s neglect sadly missed brand. Rob B